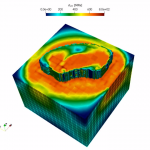

Laser Powder Bed Fusion AM Simulations

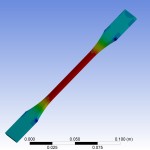

An immersed boundary approach (Finite Cell Method) to estimate the influence of different process parameters on the residual stresses and predict final distortions and residual stresses in the complete part.

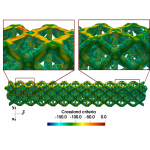

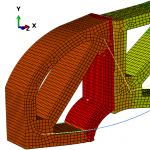

Numerical Characterization of Metal 3DPrinted Lattice Structures

A seamless immersed numerical workflow to characterize the mechanical behavior of SLM-manufactured lattices based on images obtained by computed tomography (CT).

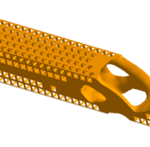

Phase-field Topology Optimization of Functionally Graded Lattice Structures

A phase-field based topology optimization procedure is developed to generate functionally graded lattice structures, i.e. lattice components with a locally varying density. A complete workflow from numerical results to 3D printed parts is implemented using in-house developed numerical tools.

Mechanical and strength modeling of FDM 3D-printed ABS

Following the mechanical characterization of FDM-printed ABS specimens, material stiffness and strength models have been developed in a linear elasticity domain. FE simulation has been carried out and preliminary results show good agreement with experimental data. To further describe the material behavior, an elastoplastic model is under study.

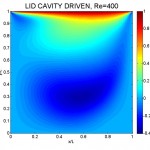

Lattice Boltzmann Methods applied to SLM modeling

Simulation of SLM process performed with Lattice Boltzmann Methods, used to simulate the powder melting and to predict the significant parameters of the process, like density, pressure and velocity.

3DPrinting Reinforced Concrete: FEA

Numerical simulations performed on the first RC 3D printed elements using different FEA software. The finite-element modeling phase is useful in support of 3d printing technology to foresee the behaviour of printed objects and as a measure of control on significative parameters.

3D Printing: From Micro to Macro Level

Predict mechanical behaviour of 3D printed specimens by FEM and analytical simulations of the sintering process, in order to characterize the heterogeneous solid as an equivalent homogeneous solid. In this way, the evolution of this technology may also contribute to the improvement of structures, guaranteeing improved efficiency during the project and efficacy during exercise.

3D-printed Bioscaffolds for Bone Transplant

3Dprinting of implantable bioscaffolds enriched by osteocytes and their calcified bone matrix, for both orthopedic, maxillofacial, and otolaryngology surgery. The scaffold will be designed and 3D printed to accomplish compact and cancellous bone features (in terms of porosity, mechanical response, and geometrical shape).

Architectured Materials Design and Print

This is a broad family of materials but holding a general idea: their properties at a global scale can be tailored as we design the topology at a small scale. This means that rather than modifying the constituents, the design is focused on adjusting the shape of small blocks (unit-cells) that when are brought together, they set up a particular material.

Bioprinting: 3D Printed Cell Constructs

Bioprinting is an innovative type of 3D printing technology for biomedical and tissue engineering purposes, based on the extrusion of biocompatible hydrogels within which cells are encapsulated. CellInk INKREDIBLE+ bioplotter has been acquired to develop new researches in various scientific fields.

3D FDM Printer customization for dispensing sodium alginate Bioink

A commercial FDM 3D printer has been customized in order to extrude viscous materials, like hydorgel. The goal is to realize 3D cell constructs used to create new cells models for disease studies for biological application.

3D printing PCL/HA scaffolds for bone tissue engineering

3D printing polycaprolactone (PCL) reinforced with hydroxyapatite (HA) to realize scaffolds for bone tissue engineering with a commercial bio-plotter. The goal is to show how the HA reinforcement brings enhancement to the scaffolds’ mechanical and biological properties, compared to plain PCL ones.

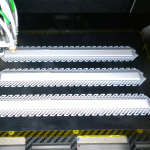

Antimicrobial filaments for FDM 3D printing

In Photo-Lab we developed an antimicrobial filament based on PLA. The “new” antimicrobial filament was used to print filters having different geometries tested for water sanitization.

4D Printing technology: much more than a dream

4D-Printing is based on the possibility to produce 3D objects that, subjected to the action of a stimuli (heat, strong vibrations, pH variations, chemicals), can change their shape.

Mechanical characterization of 3D-printed ABS

Experimental study of the printability and the mechanical behavior of fused-deposition (FD) ABS plastic material. Development of a standard procedure to characterize 3D printed materials, in terms of mechanical and strength properties.

Vegetable oils-derived resins for stereolithography

Usually resins for stereolithography are synthetic products often derived from (toxic) acrylates. We’ve developed new resins starting from commercial vegetable oils. The product obtained after the polymerization possess elastomeric properties and biodegradability.

3D Printed Patches for Esophageal Tissue Engineering

3D Printing manufacturing of esophageal patches for tissue engineering, instead of standard techniques, can lead to a significant reduction in production time and to a better customization of the scaffolds based on the specific patient’s needs, without sacrificing biological and mechanical properties.

3D Printing Concrete: Manufacturing

University of Pavia, in collaboration with University Federico II of Naples and other partners, is developing an innovative technology for printing concrete elements. Additive manufacturing allows the rethinking of conventional methods of construction, making possible shape and material optimization.

Dielectrics for high-directivity antennas

Transmitting antennas displaying very high directivity are useful in applications when signals have to travel with minimal dissipation, both regarding energy and information (connections point-to-point). To achieve these performances, the conductive part must be interfaced with dielectrics having suitable shapes. 3D printing is the right choice to obtain the prescribed geometries.

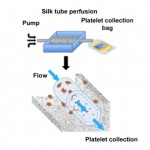

3DPrinting for Bone Marrow Modeling

Recent lab experiences by Prof. Baluini’s research group have proven that Bone Marrow Model (BMM) for haemotopoiesis is feasible by exploiting the amazing properties of the silk (biocompatibility, non-toxicity, etc.) as biomaterial. The goal of these activities is to explore the usage of 3D printing to standardize the creation of BMM favoring its scalability.

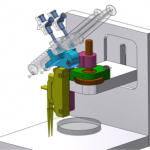

Development of Microelettrovalve for Bioprinting

One of the key components of a bioplotter is the dispensing head to drop small volumes of bioink. The purpose of these activities is to assess the performance of microelectrovalve DFD-Smart (Dolphin Fluidics) as smart dispenser for 3D Bioprinting.

Structural Applications of 3DPrinted FDM parts

Structural applications of Fused Deposition Modeling (FDM) 3d-printed parts. The main activities in this field are mechanical characterization through the definition of suitable geometry sample for tensile test, constitutive modeling, and structural optimization.

3D Printing Concrete: Tests

Starting tests performed on cylindrical samples. The tests concern mechanical performances of the printed material before and after being cured. Research on new assembly system of the steel rebar inspired by pre-stressing technology is also carrying on.

Tactile Map: 3D printing for Visual Impaired

Thanks to the contribution of Regione Lombardia, the Museum of Electrical Technology (MTE) of Pavia has created a tactile map 3D printed through FDM 3D printing technology, in cooperation with the Department of Civil Engineering and Architecture (DICAr) of the University of Pavia.

Improving quality of life: 3D printing of convector pipes

Application of Fused Deposition Modeling (FDM) 3D printing technology to produce customized convector pipes. These pipes are part of a ventilation system and help the outdoor release of unhealthy polluted air, created from the printing processes, improving indoor air quality.

Accurate reproduction of an industrial rectifier

Collaboration with Tenova S.p.A. Accurate 1:5 scale reproduction of an industrial rectifier. Binder jetting technology has been used to fabricate the various machine tool components. High chromatic and geometrical resolution of our 3D printer allowed to produce a very detailed model.

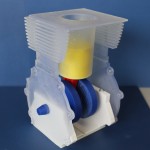

Crank mechanism manufacturing through 3D printing

Manufacturing and assembly of a crank mechanism. From the 3D virtual model, parts have been produced through two different 3D printing technologies: Fused Deposition Modeling (FDM) and Stereolithography (SLA). Afterwards they have been assembled, obtaining a working crank mechanism.

The Socio-Economic Impact

Spotlight on the analysis and measurement of the impact of 3 DAM technologies at a macro-economic and societal level.

Success Stories in 3DAM

An in-depth analysis of a portfolio of particularly interesting and disruptive case studies is being selected analysed.

Development of a Comprehensive Database on 3DPrinting

Creation of the largest database available to date with information on drivers and competitiveness in businesses that leverage 3D printing technologies in particular and Industry 4.0 paradigms in general.

A Continuous Update of Extant Academic Research and Business Reports

A first state-of-the art of available scientific and business literature, surveys and other sources is available