Introduction

Indoor air can be more polluted than outside air, according to the EPA’s Energy Star initiative. A ventilation system can improve the quality of indoor air by getting rid of pollutants. According to the EPA, indoor air pollution and stale air can create health issues, including allergies, headaches and respiratory problems, such as asthma and sinusitis. A good ventilation system protects against indoor pollutants, reducing the likelihood of these occurrences.

In FDM printing processes, a thermoplastic material filament goes through an extruder, where is heated and melted. Afterwards, the melted filament is deployed on a heated printing surface through a nozzle. Because of the material melting process, smelly and unhealthy fumes are created, polluting indoor air. Thus, a ventilation system would help to improve indoor air quality.

Idea

Building a customized ventilation system is no easy task. Parts of the right dimensions must be attached to the FDM machines and assembled together with a fan system to release polluted air outdoors.

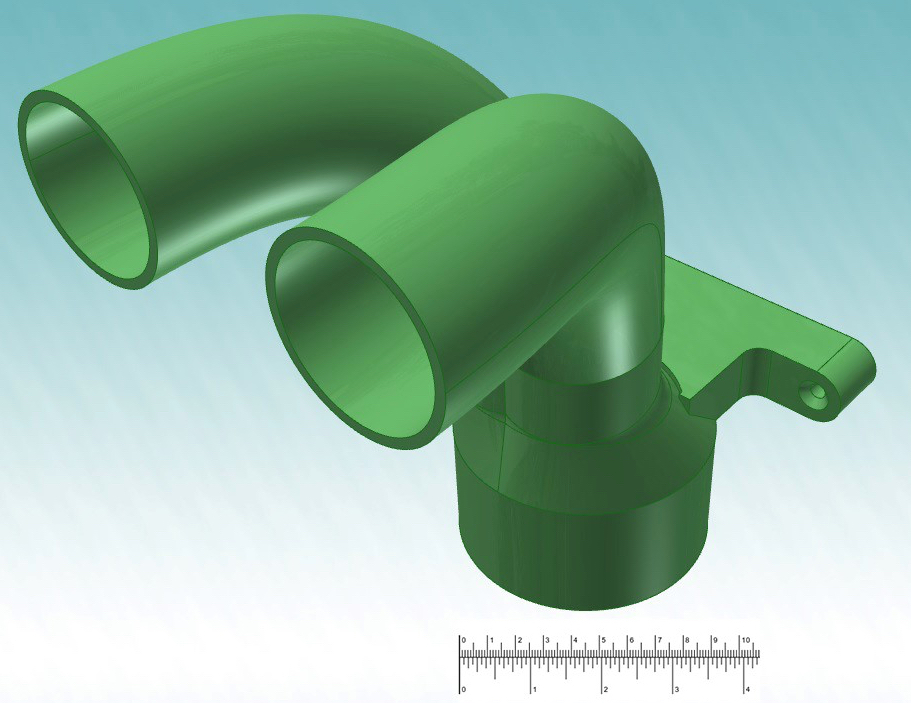

To overcome the difficulty of finding the right pipes to release these gases outside, it has been decided to use FDM technology to 3D-print ad hoc convector pipes. They are part of the ventilation system which aims to release unhealthy polluted air outdoors, improving overall quality of indoor air.

Production

Virtual 3D models of the components have been first created through a Computer Aided Design (CAD) software and then exported to a slicing software, which creates the necessary instructions to physically reproduce the desired objects. FDM technology is perfect for these situations, since it allows to realize customized parts, which have complex geometry and are strong and durable.

The components have been produced with the Leapfrog Creatr HS 3D printer. These tubes are made of Polylactic Acid (PLA), a common polymer suited to this case, since it retains good stiffness and strength. After the production, exhaust and convector pipes have been assembled and, together with a fan device, a customized ventilation system has been created.

The capability to accurately produce complex customized parts demonstrates the great versatility of 3D printing technology.