Introduction

In common practice, reinforced concrete (RC) elements with usual shapes are obtained with standardized formwork systems, while for wavy or curl beams very complex and expensive formworks are necessarily required. In this framework, 3D printing technology opens the possibility of thinking and realising shapes that are impossible to obtain with usual methods. Furthermore, this new technology is a promising step towards forms optimization and material saving, thus lightening the RC elements and reducing costs and environmental impacts.

Idea

The project of 3D printing reinforced concrete comes from the collaboration between University Federico II of Naples and University of Pavia. The idea is to exploit the potential of 3D printing technology and researchers’ knowledge on concrete mortar manufacturing and design in order to produce optimized RC elements.

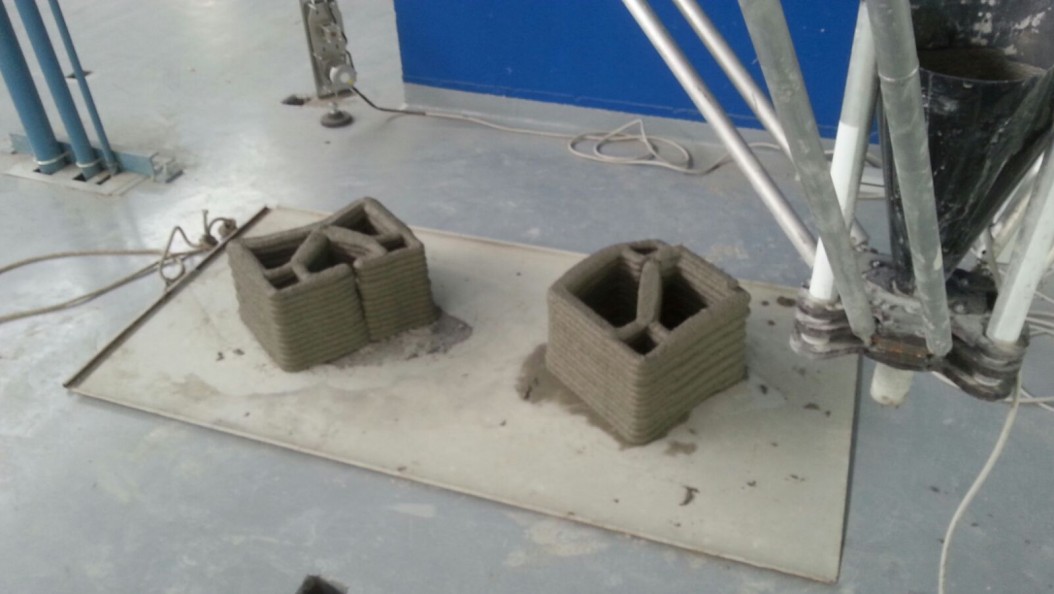

The basic idea is to cut the structural element into “segments” separately printed, then placed side by side and assembled to create complex shapes. Each segment is topologically optimized through the forecast of suitable voids. Steel rebar reinforcement is externally installed only when the assembly is completed by anchoring the bars in specific holes produced during the printing process. The rebar system has also the function of linking the segments together and lock them into a single monolithic element. For this reason, mortar or structural adhesives are employed for ensuring proper anchoring dowels for insertion into the holes.

Goals

- To manufacture RC concrete beams using the AM technology

- To enable the construction of structural elements with complex shapes and partially hollows in order to save material and optimize form, maintaining adequate mechanical properties

- To optimize printed material to balance the need of workability, extrudability and builtability

Collaborations

- Dipartimento di Strutture per l’Ingegneria e l’Architettura (DiSt), Università degli Studi di Napoli “Federico II”, Napoli, Italy

- CESMA (Advanced methodological Services Centre)

- Stress Consortium (High-tech district of the Campania region on sustainable building)

- WASP (World Advanced Saving Project)