A broad range of construction materials are daily used to address different 3D printing methods, in order to manufacture products ranging in scale from components to complete structures. Concrete 3D printing is rapidly developing: a crucial aspect is the concrete (or mortar) mix design, that should be capable to ensure the proper 3D printing process. Indeed, the fresh concrete should therefore be sufficiently strong, stiff, and stable to carry its self-weight and the weight of the layers above it, limiting deformations. As a result, experimental tests are daily performed at 3Dconcrete, mainly comparing the mechanical behaviour of early age concrete to the hardened product performances.

Fresh concrete optimization is guaranteed balancing different needs:

- Workability → mixing and pumping throughout a reasonable time interval

- Extrudability → extrusion with a continuous material flow

- Buildability → remain stacked in layers after extrusion and sustain the weight

To assure a proper material design, the following tests are performed:

- Workability → Rheological and slump tests

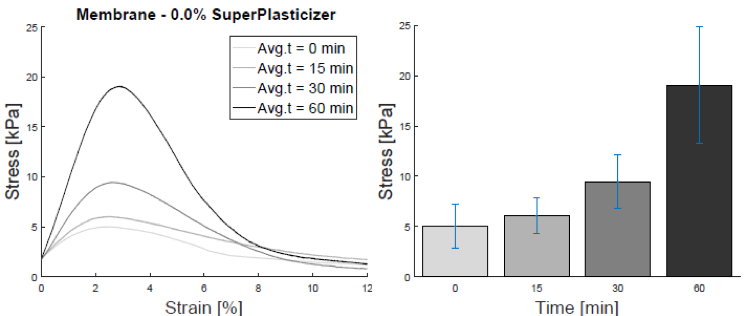

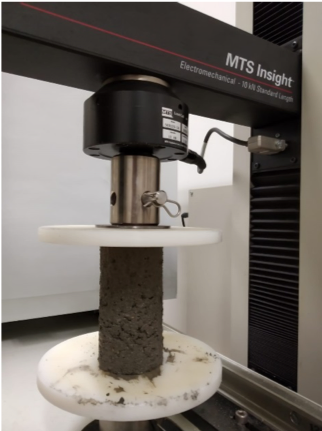

- Extrudability → Shear tests

- Buildability → Compression and creep tests

investigating on the curing time and on the influence of superplasticizer.