Introduction

Fused Deposition Modeling (FDM) is one of the most popular 3D printing process allowing to realize complex objects in a single and simple process due to its ease of use, adaptability of the system and low costs. The FDM stands out in the landscape of 3D printing to the widest range of processable materials, ranging from thermoplastic polymers with high mechanical performance, to those biocompatible, to the elastomer [1] [2]. FDM technology is limited to the use of thermoplastic filaments with a degree of roundness of not less than about 50 Shore A not allowing to process highly viscous materials such as silicone or hydrogel. For these materials it is necessary extrusion pressure based systems. More generally, 3D printing has found a great development in biomedical and tissue engineering field for scaffolds production made with biocompatible thermoplastic polymers or high viscosity materials such as hydrogels. In these compounds it is possible encapsulate cellular components such as cells, growth factors and drugs. This process, called bioprinting [3], is constantly changing: the availability of low cost 3D bioplotter supports access to bioprinting promoting research, even if today, there are limitations related to cellular cytotoxicity to the printing and long term biological survival.

Goal

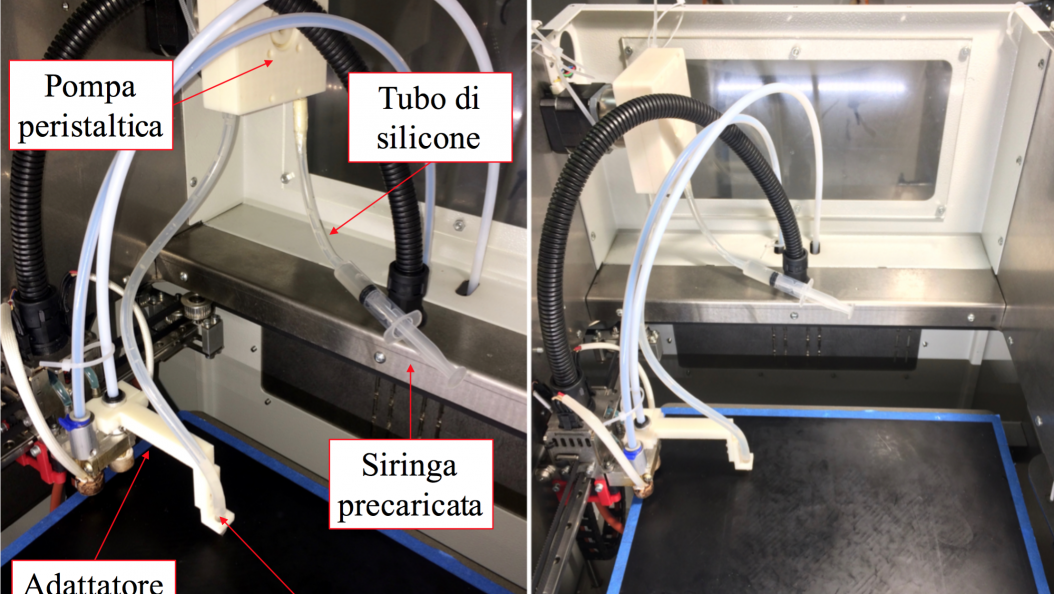

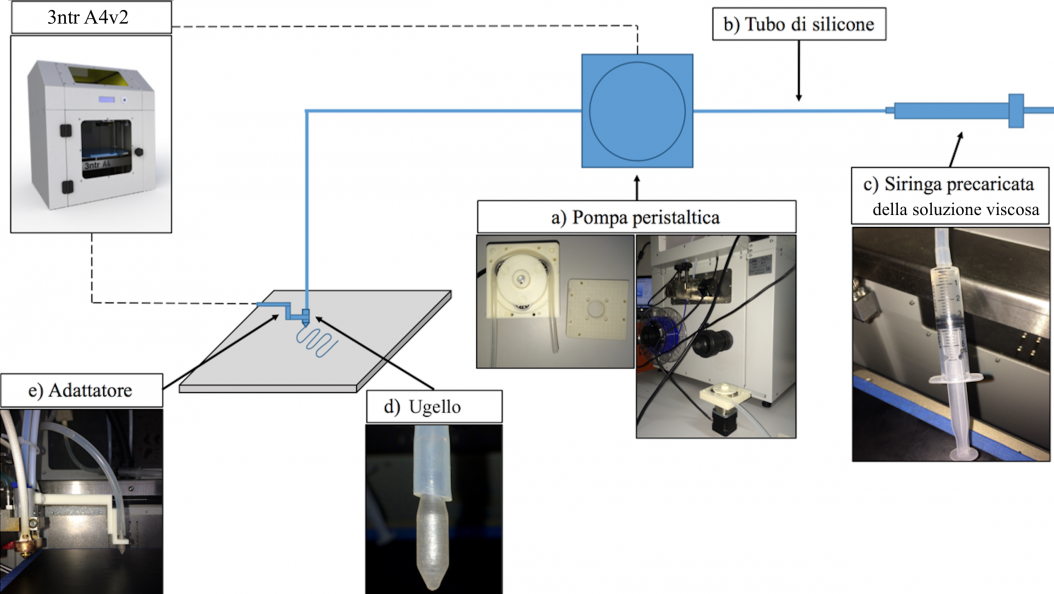

Realized a simple and low-cost system that can be extruded viscous solution as hydrogels for bioprinting applications. Customize FDM 3D printer (3ntr A4v2 of JdealForm s.r.l., Oleggio, NO) for viscous solutions extrusion as hydrogels, in order to achieve bioink based on hydrogel used to encapsulate cells.

Methods

It was set up the 3ntr A4 FDM printer to extrude sodium alginate at different concentrations. Hardware modification has provided a peristaltic pump connection to FDM printer to pick up viscous solution and dispensed it. Once verified system adaptability to print viscous solutions it has been realized bioink composed by sodium alginate, gelatin and two cells line: immortalized cancer cells (HeLa) and human neuroblastoma cells (SH-SY5Y). Bioink creation has provided for cell proliferation and viability assay suitable to detect bioink components dosage to maximize cell survival in each of the two cases. Tests have identified the better sodium alginate and gelatin bioink concentration which was extruded either manually, with standard laboratory technique, both with customized system to assess extrusion process effects on cell viability.

Results

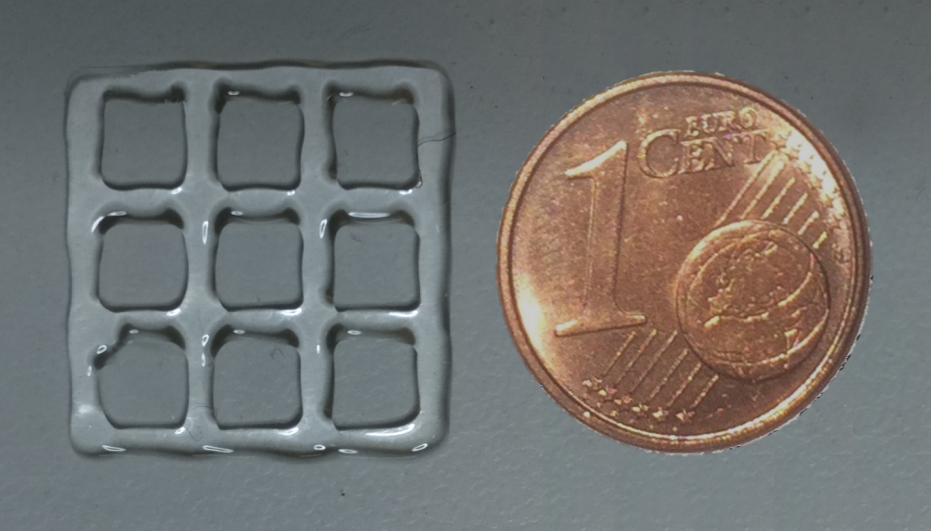

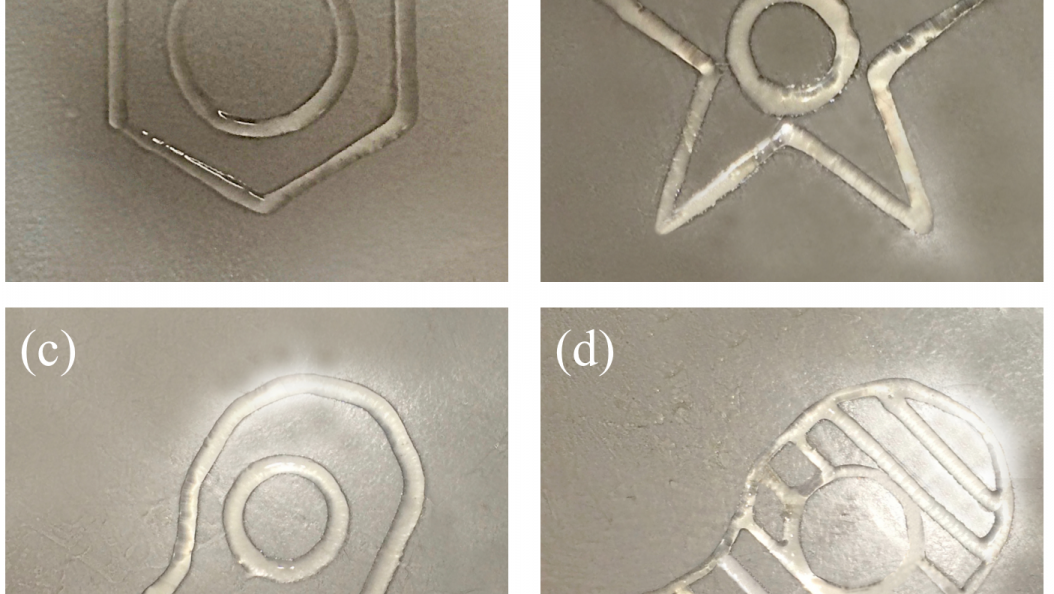

- System allows to customize a FDM printer transforming it in a system able to extrude viscous solutions like hydrogel and realized variable complexity geometries with good resolution and repeatability.

- Decreasing the amount of the extruded filament increase geometry resolution and it has been identified better sodium alginate solution concentration to ensure geometry shape, resolution and repeatability.

- It is possible create complex and asymmetrical shapes using SolidWorks software to develop CAD model and Slic3r software for slicing operation and generate G-code.

- Gelatin addition to sodium alginate solution improves proliferation without affecting printability.

- Customized system does not affect cell viability avoiding the external agents or bacteria growth and therefore is suitable for cells extrusion and future biological application.

Future developments

- Sterility conditions improvement realizing a small size 3D printer prototype having sterile room to extrude bionic or to be placed under sterile hood;

- Nozzle shape and size modification to extrude high viscous materials;

- Double extrusion to dispense different solutions in which can be encapsulated two different cell lines by printing new adapter version;

- Multilayer 3D structures printing using sodium alginate crosslinking process with calcium chloride;

- New biological tests.

References

- Gross B.C., Erkal J.E., Lockwood S.J., Chen C., and Spence D.M. Evaluation of 3D printing and its potential impact on biotechnology and chemical sciences. Analytical Chemistry, 2014.

- Dudek P. FDM 3D printing technology in manufacturing competitive elements. Archives of Meta, 2017.

- Groll J., Boland T., Blunk T., Burdick J., Cho D., Dalton P., Derby B., Forgacs G., Li K., Mironov V., Moroni L., Nakamura M., Shu W., Takeuchi S., Vozzi G., Woodfield T., Xu T., Yoo J., and Malda J. Biofabrikation: reappraising the definition of an evolving field. Biofabrication, 2016.

Collaborations

- ProtoLab, UniPv (Department of Civil Engineering and Architecture)

- Eng. Davide Ardizzoia, 3NTR – Jdeal – Form, Oleggio (NO)

- Doc. Cinzia Ferrari, Experimental Surgery Lab, University of Pavia

- Prof. Cristina Cereda, Doc. Matteo Bordoni, Doc. Valentina Fantini, IRCCS Istituto Neurologico C. Mondino, Pavia