Introduction

Injection molding is a consolidated manufacturing technology, which is widely used for physical model reproduction. However, additive manufacturing is an emerging technology which brings many advantages over traditional manufacturing methods, such as the possibility of producing complex and detailed objects very accurately.

In particular, Binder Jetting 3D printing technology is a manufacturing process, which is suited to the production of detailed parts. In Binder Jetting processes, a binding agent is selectively deposited on a layer of powder. Once a layer is finished, the powder bed is lowered and the binding agent is deposited on the next layer, till the object is completed.

Idea

Tenova S.p.A. Company requested a 1:5 scale reproduction of one of its products, an industrial rectifier. Such object had to be shown to their clients as a representative scaled model of one of their machine tools: for this reason, it had to be very accurate and every particular had to be realized with a proper color, in order to highlight its complexity and make it more pleasing to the eyes. This application has been realized as a project for the course “Virtual Modeling and Additive Manufacturing”.

Production

Binder Jetting 3D printing technology (3DSystems Projet 460 Plus) has been used for this activity. Our 3D printer uses chalk powder, a binding agent and color ink. Binder jetting technology allowed us to print a very detailed reproduction of the object. Moreover, the possibility of printing a colored version makes the final product even more aesthetically pleasant.

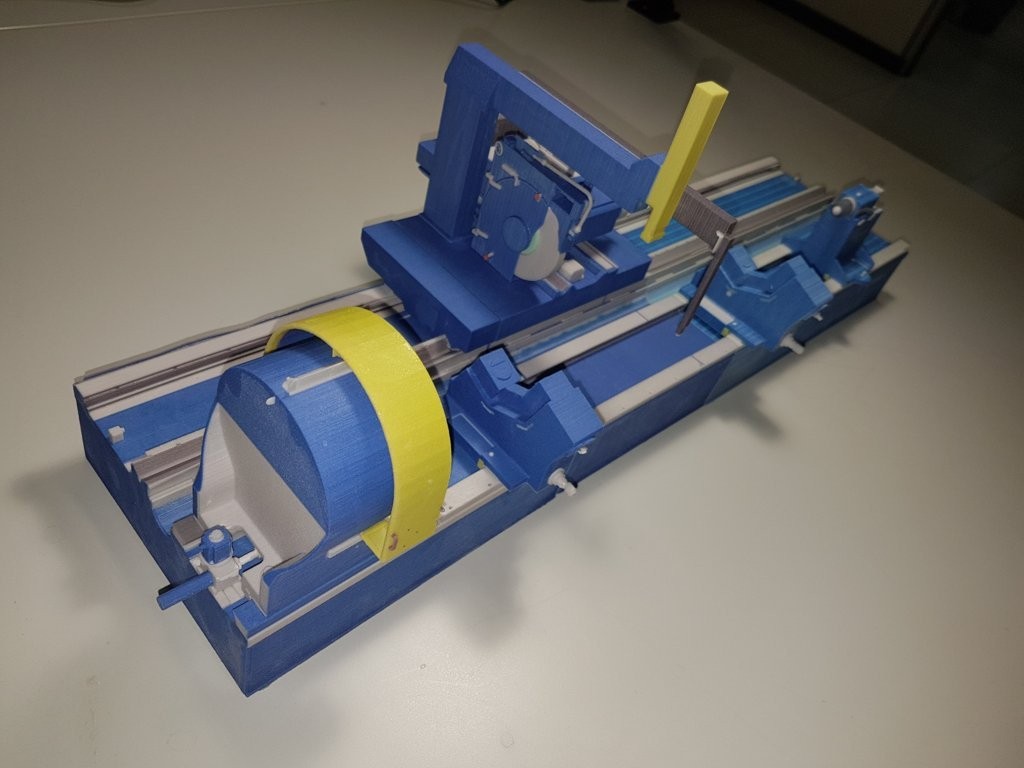

Fig. 1: Assembled 3D printed industrial rectifier

Since the object could not fit into the 3D printer, the virtual model has been initially split into smaller parts. Some students that attended the “Virtual Modeling and Additive Manufacturing” course, using the 3D printer software, selected a proper color for each machine detail. The high chromatic resolution of the 3D printer allowed them to choose from a wide range of different colors.

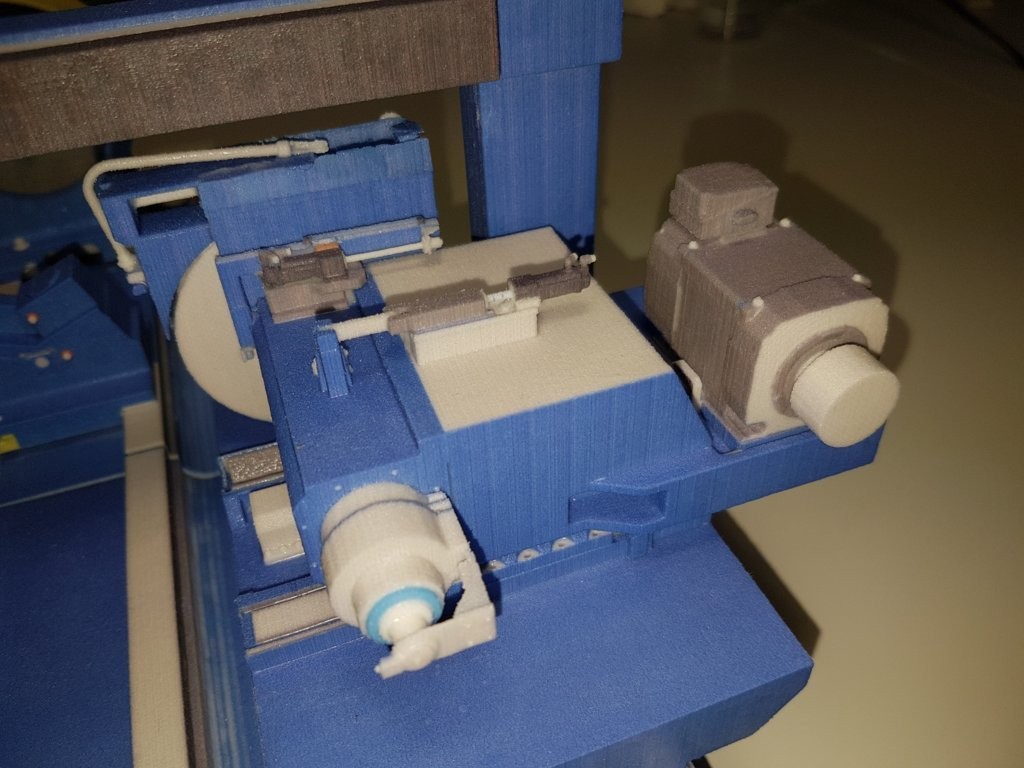

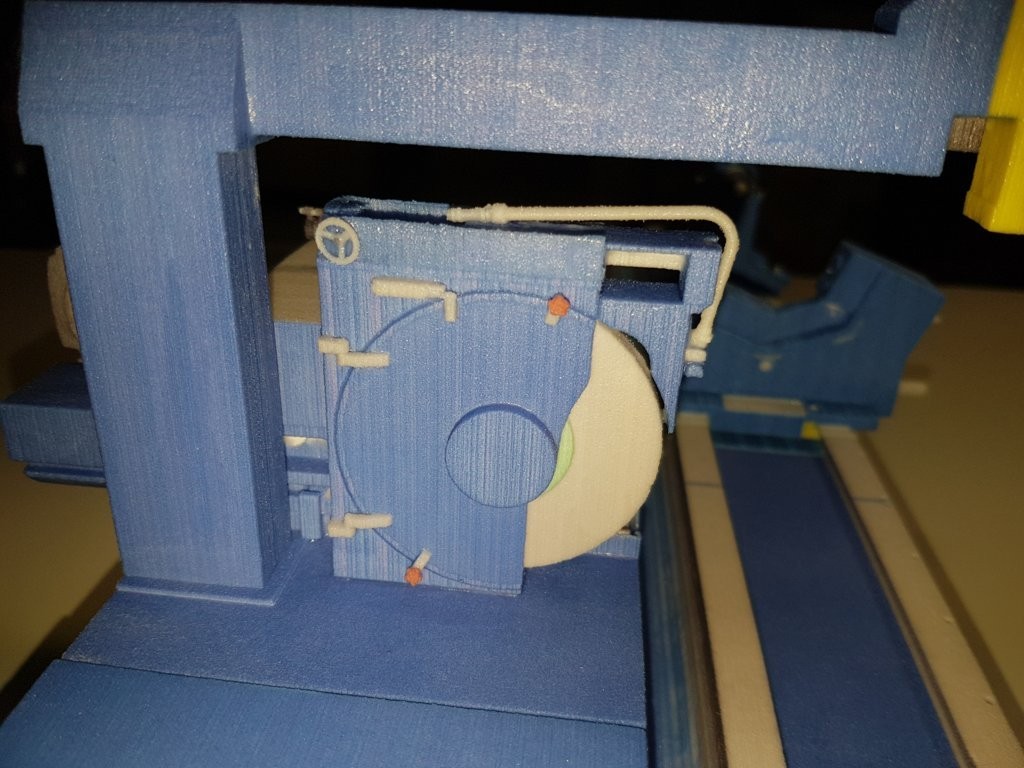

The colored parts have been subsequently printed and finally assembled together to create the final product (Fig. 1). High detailed parts of the machine tool are displayed in Fig. 2 and Fig. 3, showing that binder jetting technology can be used to reproduce complex objects with very high resolution.

Fig. 2: 3D printed industrial rectifier: detail 1

Fig. 3: 3D printed industrial rectifier: detail 2